8 Wastes According To Lean Philosophy

8 Wastes According To Lean Philosophy. We've outlined the cause and solution for all seven below, according to Lean literature, along with an eighth waste that's emerging in the construction industry Many Lean practitioners consider overproduction the worst type of waste because it is very expensive, lowers quality and contributes to other types of Kanban is a Lean manufacturing technique that was developed to reduce the waste of overproduction. Eliminating waste is at the heart of the Lean business management philosophy.

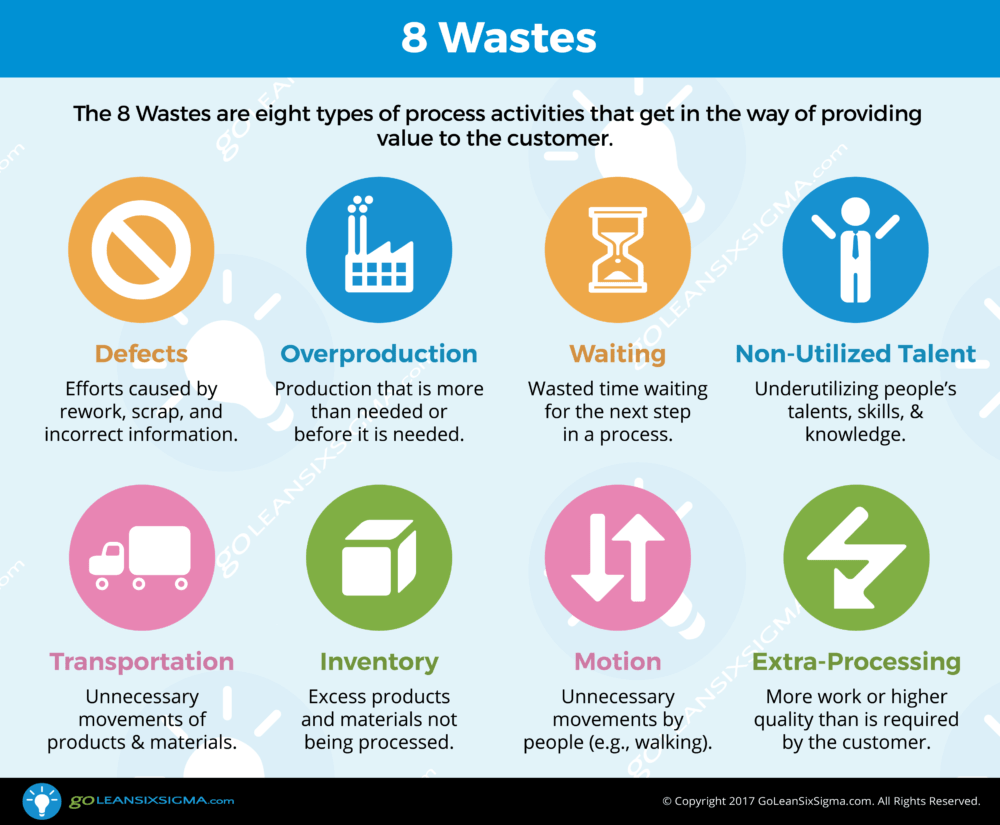

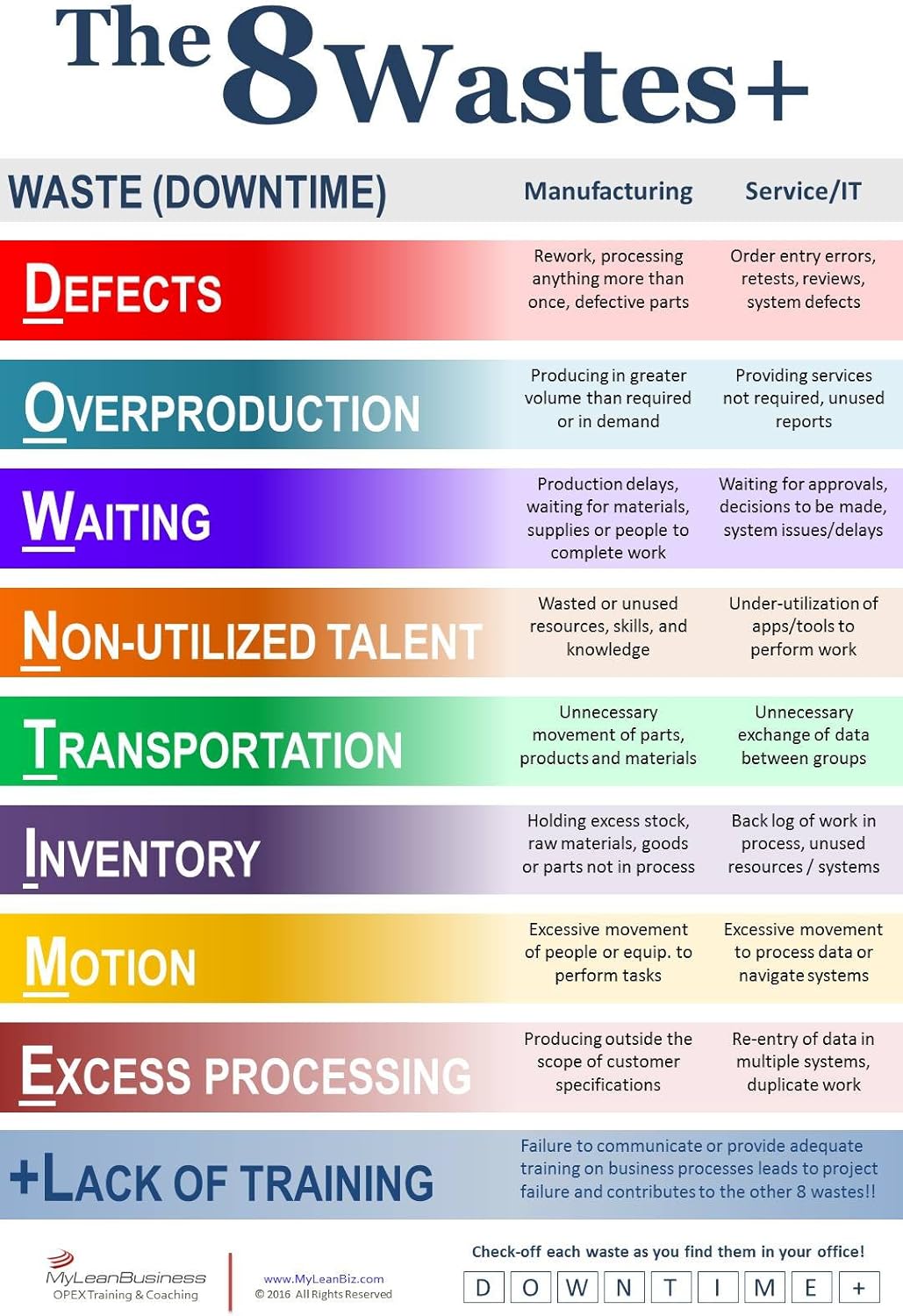

Waste can take many forms, but the basic idea is to eliminate anything and everything that does not add value from the perspective of your customer.

Under the Lean concept, if something meets ANY of the following criteria, it is considered to be waste: - does not change the information or product - is not done right the first time - the customer does not care about it or is not.

But it may also be related to the utilization of skill-sets as well as poor planning. List the eight wastes according to lean philosophy. A: The process of creating more value to the customers with the least possible resources is called Lean.

0 Response to "8 Wastes According To Lean Philosophy"

Posting Komentar