8 Wastes According To Lean Philosophy

8 Wastes According To Lean Philosophy. Even if you are not an organization devoted to the Lean approach, it still pays to understand and be on the lookout for waste that can hurt the bottom line, slow production times, hurt customer satisfaction, and demotivate. But it may also be related to the utilization of skill-sets as well as poor planning.

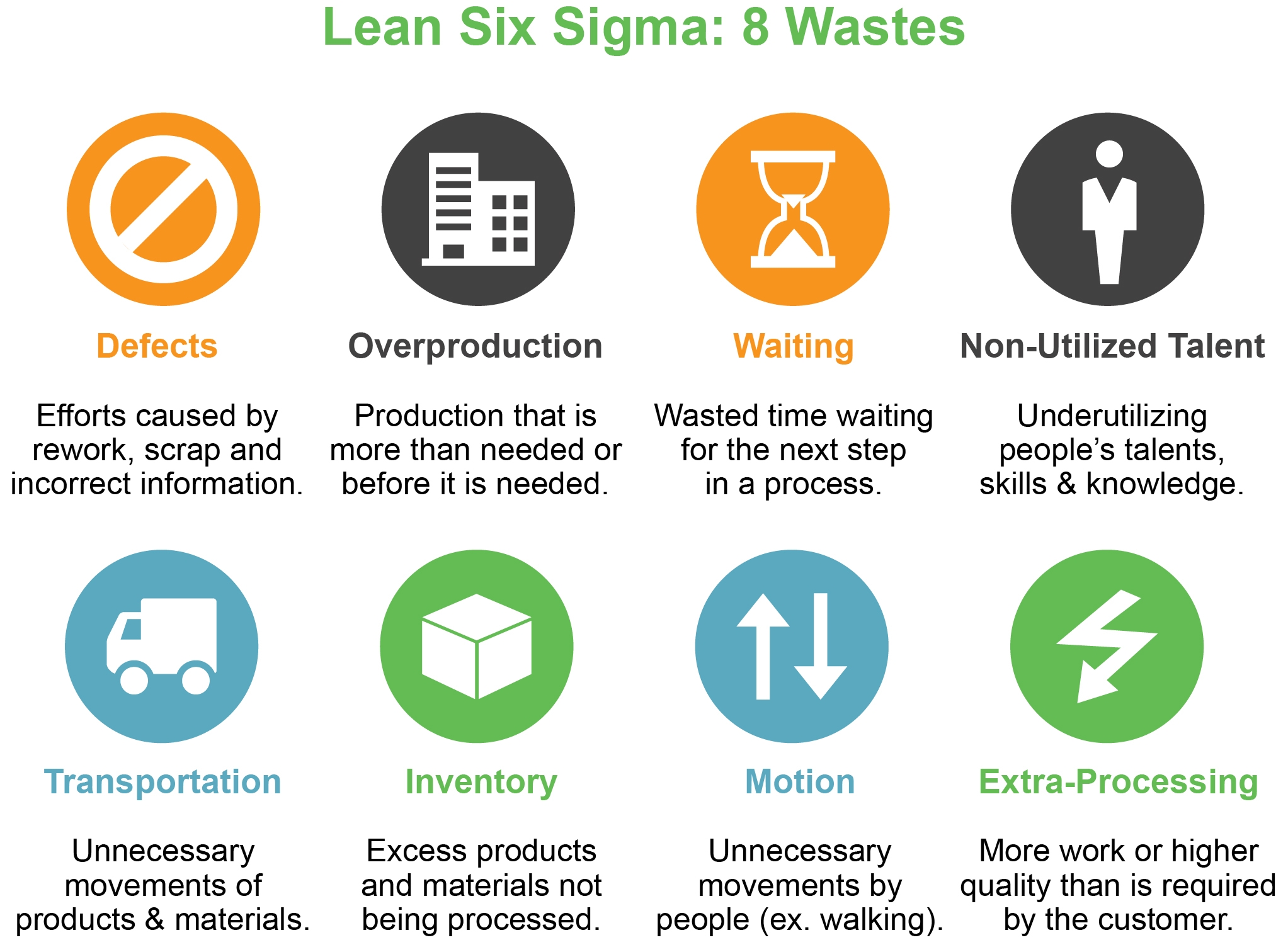

In Lean manufacturing, "waste" is commonly defined as any action that does not add value to the customer.

A Lean Consultant will teach you to see along the way so you can continue to improve your own system long after they have gone.

The original seven wastes (Muda) was developed by Taiichi Ohno, the Chief Engineer at Toyota, as part of the Toyota Production System (TPS). Lean pays importance to identifying and eliminating wastes in order to improve process performance. When you remove wastes, you are left with only the steps that are required to deliver a satisfactory.

(1).jpg)

0 Response to "8 Wastes According To Lean Philosophy"

Posting Komentar